Investment Casting

The Investment Casting process requires consistent, precise particle sizing for the building of ceramic shells.

With the acquisition of the Fused Silica business from 3M in 2025 we have added high quality Fused Silica to our product portfolio. Located in Midway, TN, this facility produces Fused Silica products optimized for purity and consistency.

From gas turbines to golf clubs, high-precision metal parts require accuracy and consistency at every stage of the manufacturing process. Engineered for use in investment casting foundries, Christy Minerals Fused Silica products include grains, flours, blends, and advanced shell systems to help meet these exacting requirements – and create parts that fit the mold every time.

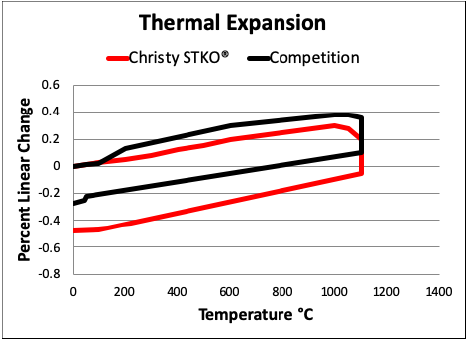

Christy Minerals STKO® Alumino-Silicate grains and flours deliver the precision performance needed for today’s Investment Caster. STKO® Alumino-Silicate contains less cristobalite so that it does not exhibit a high expansion at autoclave temperatures minimizing autoclave cracking. Christy Minerals produces a complete line of Stucco sizes and flours milled in our ceramic lined ball mill.

STKO® stuccos are constantly dedusted throughout the screening process making them virtually dust free. Christy Minerals works with customers to determine proper size for coarse to fine grains.

When your application demands superior ceramic refractory mold media, STKO® grains and flours deliver the precision performance you need.

Please contact us to find the local distributor of Christy Minerals Fused Silica and STKO® Alumino-Silicate grains and flours.